Clinker strips

- Productions

-

Blue Series

-

Clinker strips Glasgow Smooth

Clinker strips Glasgow Smooth

-

Clinker strips Glasgow deLuxe

Clinker strips Glasgow deLuxe

-

Clinker strips Neumünster

Clinker strips Neumünster

-

Clinker strips Wolfsburg

Clinker strips Wolfsburg

-

Clinker strips English Blue-brown deLuxe

Clinker strips English Blue-brown deLuxe

-

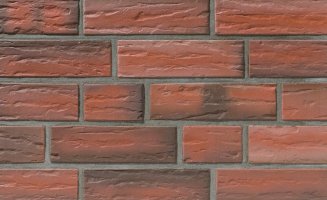

Clinker strips Red-blue Colour deLuxe

Clinker strips Red-blue Colour deLuxe

-

Clinker strips Red-blue Colour deLuxe Reverse

Clinker strips Red-blue Colour deLuxe Reverse

-

English Blue-brown deLuxe 50% Glasgow deLuxe 50%

English Blue-brown deLuxe 50% Glasgow deLuxe 50%

-

Clinker strips Red-blue Metallic deLuxe

Clinker strips Red-blue Metallic deLuxe

-

Clinker strips Dublin

Clinker strips Dublin

-

Clinker strips Dublin Alternating

Clinker strips Dublin Alternating

-

Clinker strips Dublin Reverse Sorted

Clinker strips Dublin Reverse Sorted

-

Clinker strips London

Clinker strips London

-

Clinker strips Autumn Leaves

Clinker strips Autumn Leaves

-

Clinker strips Hagen Alternating

Clinker strips Hagen Alternating

-

Clinker strips Siegen Slate

Clinker strips Siegen Slate

-

Spreda Slate

Spreda Slate

-

Grey Series

-

Clinker strips Grey deLuxe

Clinker strips Grey deLuxe

-

Clinker strips Grey-white deLuxe

Clinker strips Grey-white deLuxe

-

Clinker strips Ice-Grey deLuxe

Clinker strips Ice-Grey deLuxe

-

Silver-grey deLuxe – High

Silver-grey deLuxe – High

-

Silver-grey deLuxe – Flat

Silver-grey deLuxe – Flat

-

Beige-Grau deLuxe

Beige-Grau deLuxe

-

Göteborg

Göteborg

-

Oslo

Oslo

-

Brown Series

-

Clinker strips Moor Brown Premium

Clinker strips Moor Brown Premium

-

Clinker strips Moor Brown Premium 50% Moor Brown-black Premium 50%

Clinker strips Moor Brown Premium 50% Moor Brown-black Premium 50%

-

Moor Brown-black Premium

Moor Brown-black Premium

-

Clinker stzrips 1807 Antique

Clinker stzrips 1807 Antique

-

Colour Series

-

Clinker strips Patina Smooth

Clinker strips Patina Smooth

-

Clinker strips Patina Smooth

Clinker strips Patina Smooth

-

Clinker strips Patina Bark Sanded

Clinker strips Patina Bark Sanded

-

Clinker strips Patina Bark Unsanded

Clinker strips Patina Bark Unsanded

-

Clinker strips Patina Rustica Sanded

Clinker strips Patina Rustica Sanded

-

Clinker strips Patina Rustica Unsanded

Clinker strips Patina Rustica Unsanded

-

Clinker strips Gent

Clinker strips Gent

-

Clinker strips Patina Hand-moulded

Clinker strips Patina Hand-moulded

-

Clinker strips Colour Premium

Clinker strips Colour Premium

-

Clinker strips Florenz

Clinker strips Florenz

-

Clinker strips 1907

Clinker strips 1907

-

Clinker strips 1707 Antique

Clinker strips 1707 Antique

-

Red Series

-

Clinker strips Ruby-red water-struck

Clinker strips Ruby-red water-struck

-

Clinker strips Ruby-red Hand-moulded

Clinker strips Ruby-red Hand-moulded

-

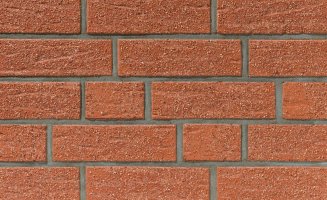

Clinker strips Red Premium

Clinker strips Red Premium

-

Clinker strips Ruby-red Bark Sanded

Clinker strips Ruby-red Bark Sanded

-

Clinker strips Ruby-red Bark Unsanded

Clinker strips Ruby-red Bark Unsanded

-

Clinker strips Ruby-red Rustica Sanded

Clinker strips Ruby-red Rustica Sanded

-

Clinker strips Ruby-red Rustica Unsanded

Clinker strips Ruby-red Rustica Unsanded

-

Ruby-red Smooth

Ruby-red Smooth

-

Alster

Alster

-

Clinker strips Daren

Clinker strips Daren

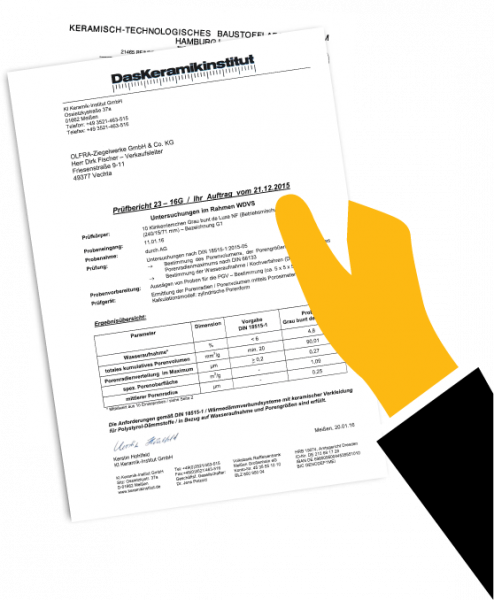

Experience, tradition and know-how – quality made in Germany

OLFRY is a family business in the best sense of the word: family-run, classically conservative yet dynamic enough to operate innovatively and successfully on the market for more than 100 years thanks to its flat hierarchies. Quality product “Made in Germany” is part of the OLFRY DNA. In addition to our own internal auditing, regular certification by independent institutes ensures our high quality standard.

Guaranteed fire-sealed

OLFRY clinker strips are now certified by the Deutsches Institut für Bautechnik for various mineral wool/styrofoam systems. Just give us a call!

Sustainable construction with clinker strips: we’ll show you how it’s done.

Watch the image film about OLFRY clinker strips made in cooperation with JUWÖ Poroton-Werke Ernst Jungk & Sohn GmbH and SAKRET Trockenbaustoffe Europa GmbH & Co. KG.

OLFRY clinker strips not only look good, they also deliver what they promise. When used in combination with the highly insulating ThermoPlan brickwork made by the JUWÖ Poroton-Werke, no additional insulation is necessary. OLFRY’s robust clinker strips are fired at over 1,100°C just like normal bricks and provide an ideal protective shield. SAKRET dry construction materials also provide optimum support and are weather-resistant.

They are frost-proof, provide permanent protection against wind and weather, reliably prevent algae infestation or woodpecker damage without chemical treatment and, unlike plaster façades, are virtually maintenance-free.

The perfect shield

When it comes to new buildings, a double-shell wall with a brick façade is the ideal choice. If this construction is not possible in certain cases, external thermal insulation composite systems (ETICS) have established themselves as an alternative. These combinations of backing masonry and insulating layer are also used in façade renovation and require a high-quality outer protective layer that protects the sensitive thermal insulation from all external influences.

OLFRY produces clinker strips for this application. The thin bricks and clinkers are simply stuck to the thermal insulation and then pointed. As they are fired at over 1,100°C just like normal bricks, they have the same properties: their play of colours is genuine, they can be individually combined and ensure a healthy living climate due to their natural origin.

However, what makes these clinker strips predestined as an outer protective layer in ETICS is their exceptional robustness: just like in a facing brick façade, they are frost-proof, provide permanent protection against wind and weather, reliably prevent algae infestation or woodpecker damage without chemical treatment and, unlike plaster façades, are virtually maintenance-free.

In short: OLFRY clinker strips are practically indestructible and thus ensure the lasting value of your house for years to come. Almost all of our brick and clinker types are also available as standard clinker strips. Depending on the application, however, there are some special features that our clinker specialists will be happy to explain to you. Simply arrange an expert consultation!

Clinker strips are used not only for renovations, but increasingly also for new buildings and conversions.

The manufacturing technique of OLFRY clinker strips is of great importance for their optics. As they are cut from the full brick, an OLFRY clinker strip never looks like a tile. Clinker strips may be thin, but they are full-fledged facing bricks that are classified as coarse ceramics. Corner and runner clinker strips are used to clad building corners, window lintels and jambs. A façade made of clinker strips cannot be distinguished from a conventional brick façade. As they are cut from the full brick, clinker strips can be easily combined with whole clinkers and bricks – as there are no colour deviations.

Proven quality

Clinker strips for every type of application

External thermal insulation composite systems require an approval from the German Institute for Building Technology (DIBt, Berlin), which is issued only for the entire system and is limited in time. Special requirements are also placed on the clinker strips, which serve as a protective layer for the underlying ETICS (polystyrene and/or mineral wool). In particular, the water absorption must be very low (water absorption according to DIN EN 14411, boiling method).