Experience OLFRY

Facts & Figures

In business for more than 100 years

OLFRY is a family business in the best sense of the word: family-run, classically conservative yet dynamic enough to operate innovatively and successfully on the market for more than 100 years thanks to its flat hierarchies.

Experience, tradition and know-how – quality made in Germany

OLFRY is a family business in the best sense of the word: family-run, classically conservative yet dynamic enough to operate innovatively and successfully on the market for more than 100 years thanks to its flat hierarchies. Quality product “Made in Germany” is part of the OLFRY DNA. In addition to our own internal auditing, regular certification by independent institutes ensures our high quality standard.

Exhibition

Anyone wanting to build a house with a brick façade will be interested in finding the right clinker brick from the earliest planning phase. Building project managers who are well informed and competently advised by the architect or manufacturer will find the right brick for their house.

Every kind of architecture has its own clinker brick that fits best. For contemporary styles, architects usually recommend a dark, blue-brown clinker brick. The North German clinkers in bright brick red with a blue edge match the style of a modern Frisian house, while a dark red clinker is often chosen for a Westphalian country house.

For all architectural styles, it is important to find the brick that fits best and the best material combinations for windows, doors and roof tiles. When selecting these elements, care should be taken to ensure that the colour and surface structure match the clinker brick. OLFRY offers a good opportunity to check this out in its brick exhibition. It features combinations of clinker surfaces with roof tiles and window profiles. But you also have the option of placing material samples you have brought yourself to the front of the sample wall of the desired clinker in order to examine the effect.

Regardless of whether you are building turnkey or individually with your own architect – every client should get an idea of the large selection in advance.

The complete OLFRY brick range is available for viewing at our premises (Friesenstraße 9–11) on weekdays from

8 am to 5 pm.

The OLFRY model garden at McDonald’s (corner of Friesenstraße/Lohner Straße) can be visited at any time.

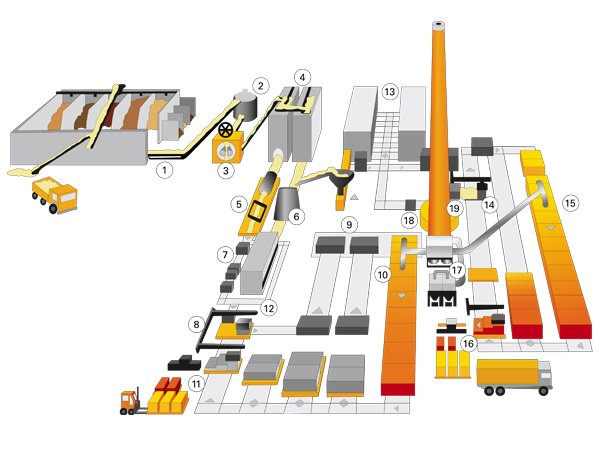

Our production

1Clay storage hall

2Pan grinder

3 Rolling mills

4 Clay silos

5Extrusion press

6 Water-struck press

7 Chamber dryer

8Setting plant

9Preheater

10Tunnel kiln

11Destacking and sorting plant

12Hand moulding press

13Chamber drying

14 Hand moulding plant

15Tunnel kiln

16Packaging line

17Flue gas cleaning plant

18Chimney

19Control centre

Environmental protection

- 1. Sand

2. Hydrated lime

3. Grit (carrier material)

4. Lime milk conditioner

5. Reactivator

6. Stripping machine

7. Fabric filter

8. Deep-bed reactor

9. Chimney

10. Tunnel kiln

11. Heat recovery

12. Residual product

To protect the environment as far as possible from harmful exhaust gases is a highly desirable goal. OLFRY has come a lot closer to reaching this goal. We were the first European brickworks to install an innovative flue gas cleaning plant that filters not only fluorine but also sulphur from the exhaust gases, thereby saving primary energy (e.g. natural gas) through heat recovery and slowing down the warming of the Earth’s atmosphere.

The process is a dry, wastewater-free system based on hydrated lime. Two deep-bed reactors prevent around 300 tonnes of sulphur dioxide from escaping into the atmosphere every year.

The amount of heat generated by flue gas cooling could be used to heat 20 single-family homes. It is used in the cleaning process, among other things, and partially replaces other heat sources during operation.

Conserving resources

The sustainable use of natural resources is a top priority at OLFRY. Because of this, we attach great importance to comprehensive energy management, which monitors the use of resources such as electricity and natural gas and continuously reduces energy consumption and CO2 emissions. Despite steadily increasing production volumes by up to 50%, energy consumption has been kept stable since 2010, for example.

OLFRY’s energy management has been certified by independent testing laboratories and is continuously monitored by means of regular audits.